Interview: From Master’s student to project manager in Automotive.

Vivien Rumpf about an automotive department, hierarchies at Elektrosil and challenges while studying.

Vivien, you are an “Automotive OEM Project Manager” at Elektrosil; what does that mean?

In the automotive department, we manage projects for car manufacturers for all the parts that can be installed in a vehicle.

We usually receive customer enquiries and process the project from the initial enquiry to the series handover to our merchandise management team. This involves going through different phases: the requirement phase, the definition phase, the A-sample, the B-sample, and the C-sample, and finally, the handover to series production.

I am part of the project management team. We take care of all customer tasks, distribute them within the company, and answer all open questions from customers. We also make sure that all deadlines are met, for example, that we receive all information and samples right time and can provide them.

What skills are crucial for a project manager?

I think it's the combination of organizational talent and communication skills. Then there's time management - to meet customer deadlines, and flexibility. Because sometimes you must find solutions to problems quickly if something doesn't go as planned.

Hands-on work as a project manager: Vivien pushes seat air conditioning fans for vehicle seats into the burn-in oven

How did you come to Elektrosil?

Hands-on work as a project manager: Vivien pushes seat air conditioning fans for vehicle seats into the burn-in oven

How did you come to Elektrosil?

I found the job via the “Job for Masters” program on the Nordakademie homepage and then submitted my application.

Our CEOs, Hendrik Niemann and Hannes Collenburg, invited me to an interview and asked me a few questions, such as what direction I see myself going in and what my strengths and weaknesses are. They thought I would be a good fit for the automotive team.

After six months of familiarization with the department, I started at Elektrosil alongside my studies. This gave me a bit of time to get to know the topics and the department's processes.

Initially, I was involved in internal projects, then took on projects in the Tier 2 sector, and finally worked on projects for OEMs. That was an excellent way to start slowly with the automotive business and only then take on responsibility for larger projects.

How did the Master's program go alongside your work at Elektrosil?

The degree program lasts two years. The Nordakademie specifies exactly when each lecture takes place. You then have 6 to 8 weeks of preparation and 2.5 days of lectures in attendance. The company released me from work so I could concentrate fully on the university. 3 to 4 weeks after the attendance phase I wrote an exam or a term paper. The next subject only starts once the block for one subject is completed. Once you have completed all the subjects, you can start your Master's thesis.

In my opinion, this is more relaxed than at other universities, where you have all the subjects simultaneously and have to take the exams at the end of the semester. Of course, it was much work and sometimes exhausting to study after work or at weekends and to find time for hobbies. But you have the advantage of working in the company all the time and being able to supervise long-term projects in one go, thanks to the short periods of attendance.

Aluminium and plastic fan for a car manufacturer

What are the hierarchies in the company?

Aluminium and plastic fan for a car manufacturer

What are the hierarchies in the company?

The hierarchy at Elektrosil is relatively simple. Pascal Frank, the head of the automotive department, is our direct superior, and Hannes and Hendrik are above him as managing directors. It's a flat structure.

How do your superiors support you?

For my final thesis, I had a few brainstorming sessions with Hannes, Hendrik and Pascal to find a suitable topic for my Master's thesis. Together, we found a topic that matched my interests and could also help the company. I wrote about implementing series assembly for medium-sized companies in the automotive industry using the example of fan assembly.

Pascal and Hannes then read my Master's thesis before I submitted it and gave me valuable advice.

What do you wish for Elektrosil's future?

My wish for Elektrosil is that many new projects continue to come in and that we work together on the challenges.

Hands-on work as a project manager: Vivien pushes seat air conditioning fans for vehicle seats into the burn-in oven

How did you come to Elektrosil?

I found the job via the “Job for Masters” program on the Nordakademie homepage and then submitted my application.

Our CEOs, Hendrik Niemann and Hannes Collenburg, invited me to an interview and asked me a few questions, such as what direction I see myself going in and what my strengths and weaknesses are. They thought I would be a good fit for the automotive team.

After six months of familiarization with the department, I started at Elektrosil alongside my studies. This gave me a bit of time to get to know the topics and the department's processes.

Initially, I was involved in internal projects, then took on projects in the Tier 2 sector, and finally worked on projects for OEMs. That was an excellent way to start slowly with the automotive business and only then take on responsibility for larger projects.

How did the Master's program go alongside your work at Elektrosil?

The degree program lasts two years. The Nordakademie specifies exactly when each lecture takes place. You then have 6 to 8 weeks of preparation and 2.5 days of lectures in attendance. The company released me from work so I could concentrate fully on the university. 3 to 4 weeks after the attendance phase I wrote an exam or a term paper. The next subject only starts once the block for one subject is completed. Once you have completed all the subjects, you can start your Master's thesis.

In my opinion, this is more relaxed than at other universities, where you have all the subjects simultaneously and have to take the exams at the end of the semester. Of course, it was much work and sometimes exhausting to study after work or at weekends and to find time for hobbies. But you have the advantage of working in the company all the time and being able to supervise long-term projects in one go, thanks to the short periods of attendance.

Hands-on work as a project manager: Vivien pushes seat air conditioning fans for vehicle seats into the burn-in oven

How did you come to Elektrosil?

I found the job via the “Job for Masters” program on the Nordakademie homepage and then submitted my application.

Our CEOs, Hendrik Niemann and Hannes Collenburg, invited me to an interview and asked me a few questions, such as what direction I see myself going in and what my strengths and weaknesses are. They thought I would be a good fit for the automotive team.

After six months of familiarization with the department, I started at Elektrosil alongside my studies. This gave me a bit of time to get to know the topics and the department's processes.

Initially, I was involved in internal projects, then took on projects in the Tier 2 sector, and finally worked on projects for OEMs. That was an excellent way to start slowly with the automotive business and only then take on responsibility for larger projects.

How did the Master's program go alongside your work at Elektrosil?

The degree program lasts two years. The Nordakademie specifies exactly when each lecture takes place. You then have 6 to 8 weeks of preparation and 2.5 days of lectures in attendance. The company released me from work so I could concentrate fully on the university. 3 to 4 weeks after the attendance phase I wrote an exam or a term paper. The next subject only starts once the block for one subject is completed. Once you have completed all the subjects, you can start your Master's thesis.

In my opinion, this is more relaxed than at other universities, where you have all the subjects simultaneously and have to take the exams at the end of the semester. Of course, it was much work and sometimes exhausting to study after work or at weekends and to find time for hobbies. But you have the advantage of working in the company all the time and being able to supervise long-term projects in one go, thanks to the short periods of attendance.

Aluminium and plastic fan for a car manufacturer

What are the hierarchies in the company?

The hierarchy at Elektrosil is relatively simple. Pascal Frank, the head of the automotive department, is our direct superior, and Hannes and Hendrik are above him as managing directors. It's a flat structure.

How do your superiors support you?

For my final thesis, I had a few brainstorming sessions with Hannes, Hendrik and Pascal to find a suitable topic for my Master's thesis. Together, we found a topic that matched my interests and could also help the company. I wrote about implementing series assembly for medium-sized companies in the automotive industry using the example of fan assembly.

Pascal and Hannes then read my Master's thesis before I submitted it and gave me valuable advice.

What do you wish for Elektrosil's future?

My wish for Elektrosil is that many new projects continue to come in and that we work together on the challenges.

Aluminium and plastic fan for a car manufacturer

What are the hierarchies in the company?

The hierarchy at Elektrosil is relatively simple. Pascal Frank, the head of the automotive department, is our direct superior, and Hannes and Hendrik are above him as managing directors. It's a flat structure.

How do your superiors support you?

For my final thesis, I had a few brainstorming sessions with Hannes, Hendrik and Pascal to find a suitable topic for my Master's thesis. Together, we found a topic that matched my interests and could also help the company. I wrote about implementing series assembly for medium-sized companies in the automotive industry using the example of fan assembly.

Pascal and Hannes then read my Master's thesis before I submitted it and gave me valuable advice.

What do you wish for Elektrosil's future?

My wish for Elektrosil is that many new projects continue to come in and that we work together on the challenges.

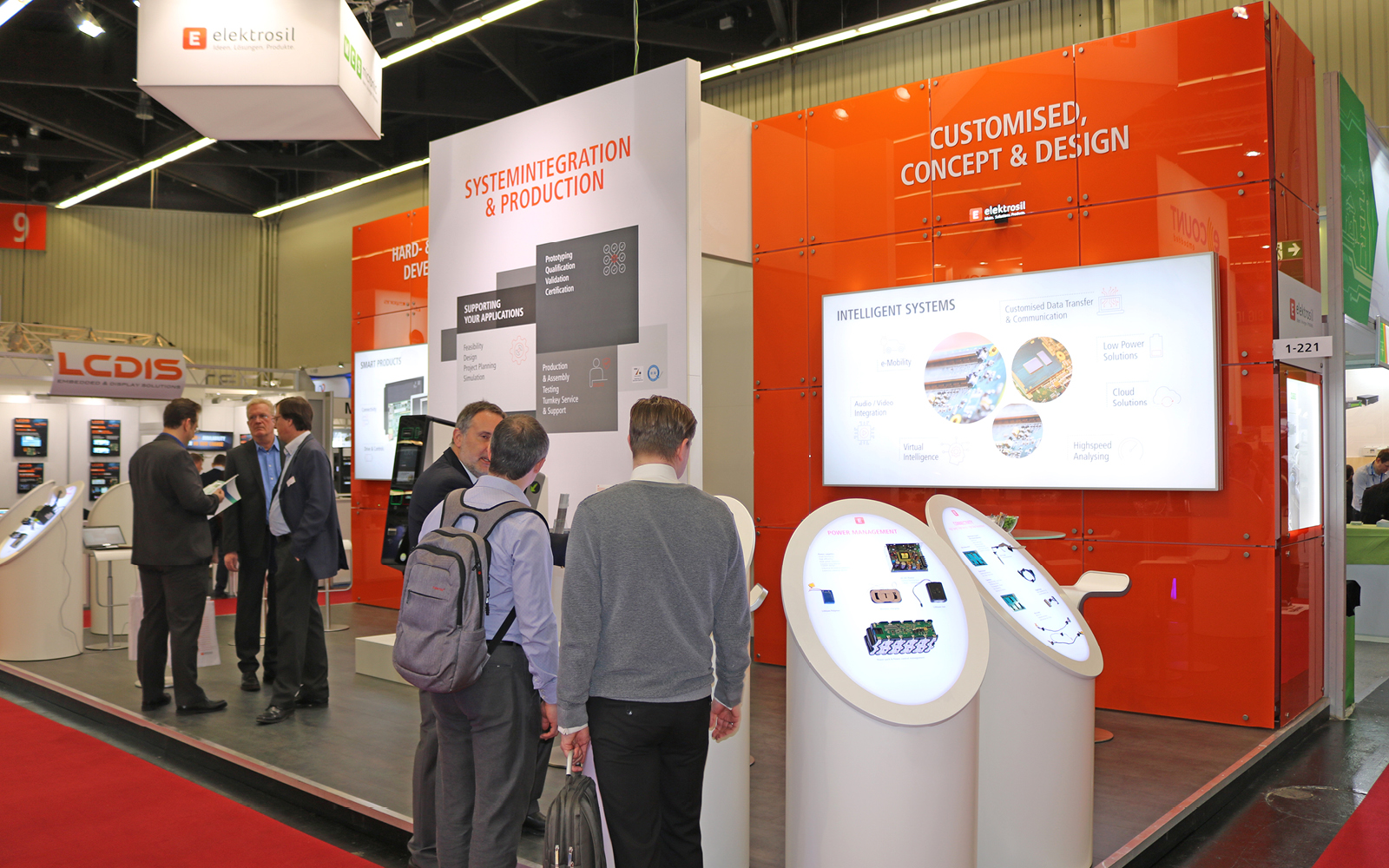

Photos and booth concept:

Photos and booth concept:

Photos and booth concept:

Photos and booth concept:

Photos and booth concept:

Photos and booth concept:

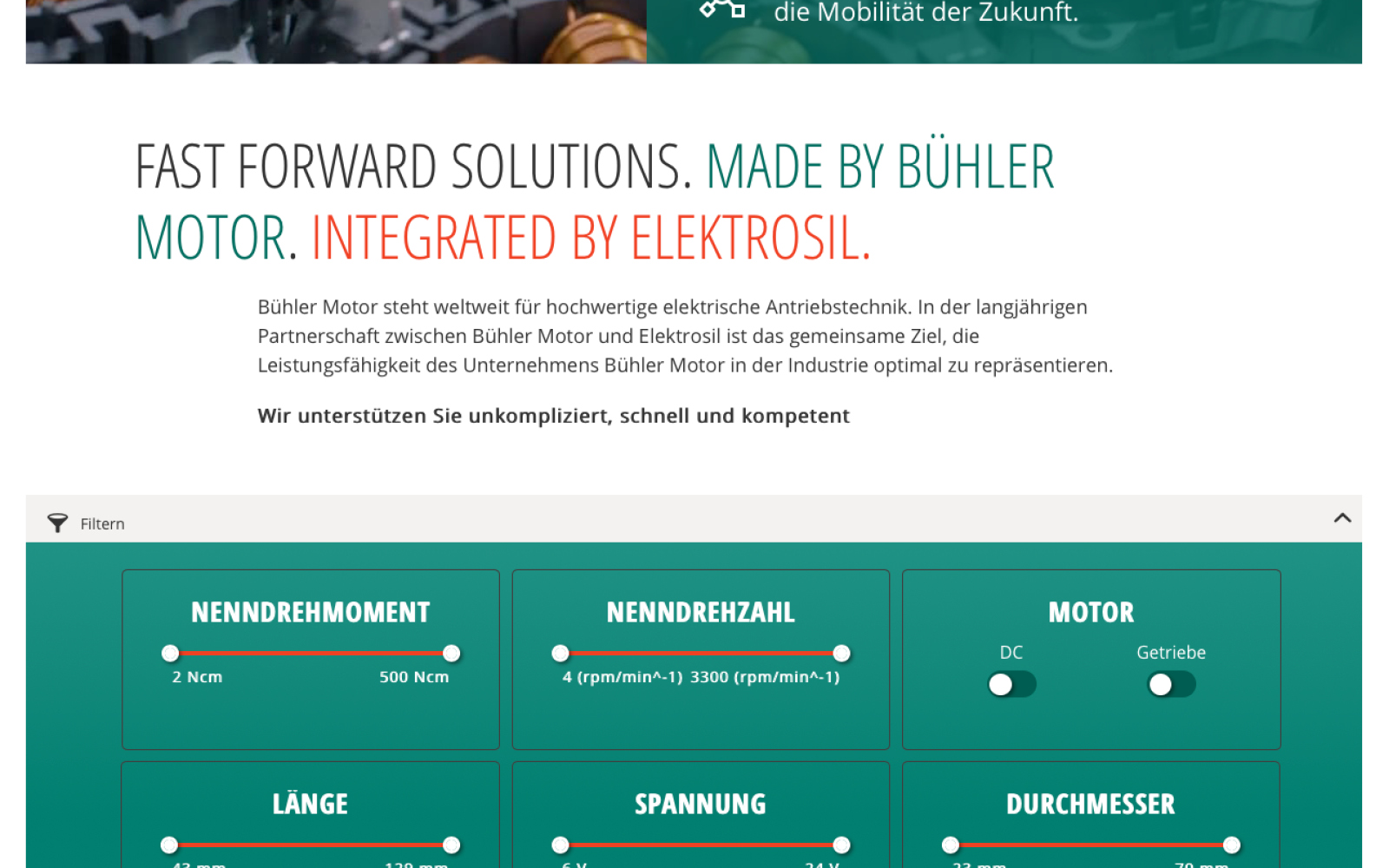

The team from Bühler Motor and Elektrosil at the presentation of the new shop at the SPS in Nuremberg. Elektrosil CEO Hendrik Niemann and Bühler Motor Manager Global Sales & Marketing Andreas Welzenbach congratulate each other on their good cooperation.

The team from Bühler Motor and Elektrosil at the presentation of the new shop at the SPS in Nuremberg. Elektrosil CEO Hendrik Niemann and Bühler Motor Manager Global Sales & Marketing Andreas Welzenbach congratulate each other on their good cooperation.